Products & Applications

Product Categories

○ Product Details

I. Product Applications

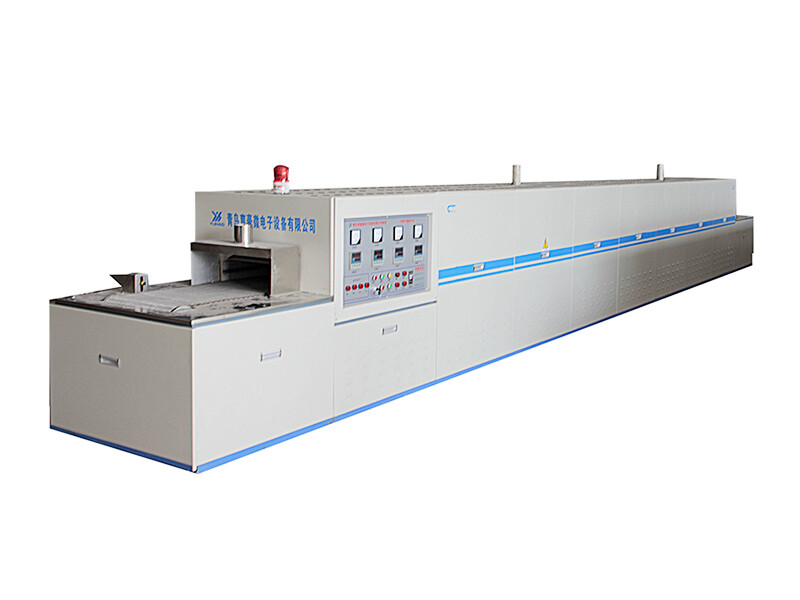

Primarily used for various electronic components, diodes, rectifiers, automotive electronics, and other products held by tweezers in inkjet tools, combined with solder paste, solder sheets, and related soldering materials for production processes under vacuum or protective atmosphere environments. The equipment mainly consists of heating systems, gas systems, cooling systems, transmission systems, electrical control systems, vacuum systems, and frames.

One-click automatic completion of process production, with multiple process curve settings for convenient retrieval and use.

II. Key Parameters:

III. Main Features and Advantages

1) The equipment features vacuum extraction, heating, gas filling, exhaust, and furnace alarm functions;

2) Adopts computer control, with operations performed via a liquid crystal display interface, offering both automatic and manual operation modes (user management control can be implemented; software can set permissions, allowing engineers to modify process parameters while operators can only execute programs without altering any parameters).

3) Automatic operation steps can be set for vacuum extraction and gas filling times based on process requirements. Once edited, the program can be saved, called, and executed automatically.

4) Real-time temperature measurement and graphical output during operation, with data saved in time format for随时查阅、存储及打印。

○ Company Profile

Qingdao Yuhao Microelectronics Equipment Co., Ltd. was established in 2008 as a high-tech enterprise integrating R&D, manufacturing, and sales. The company specializes in electric heating furnace equipment, heating furnace thermal fields, and graphite tool processing. Our products and services cater to various industries including electronic components, semiconductor materials, and solar photovoltaic sectors.

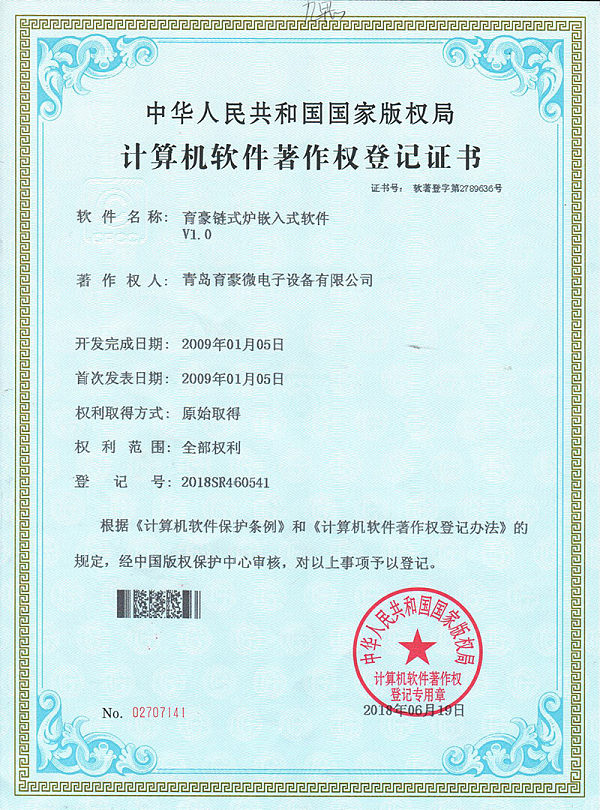

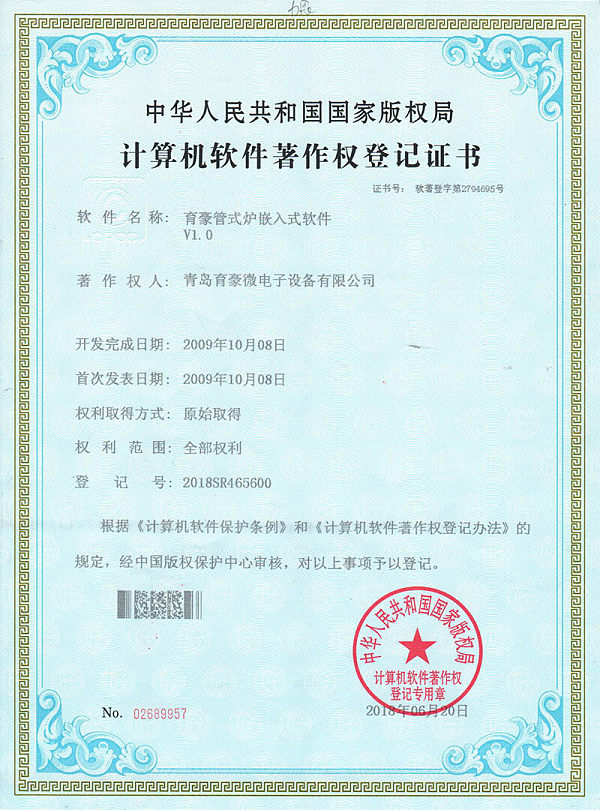

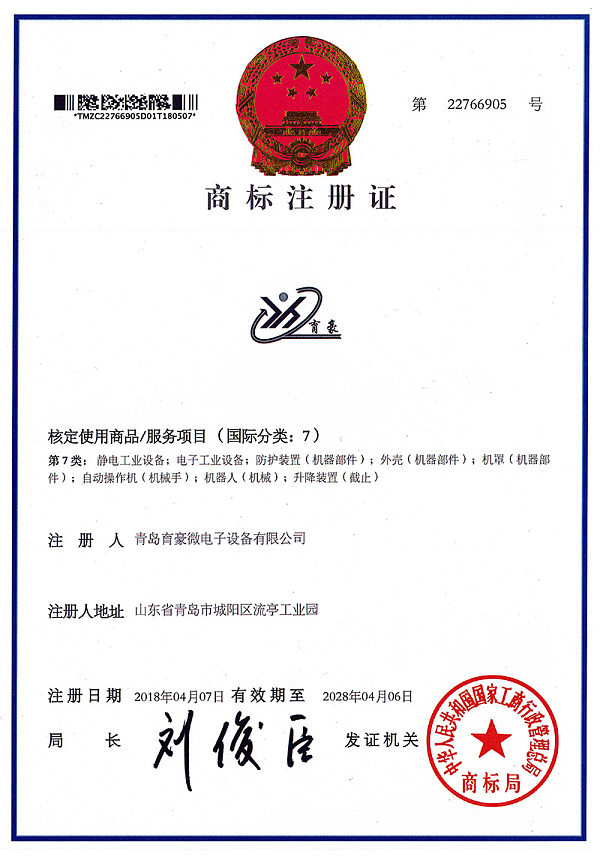

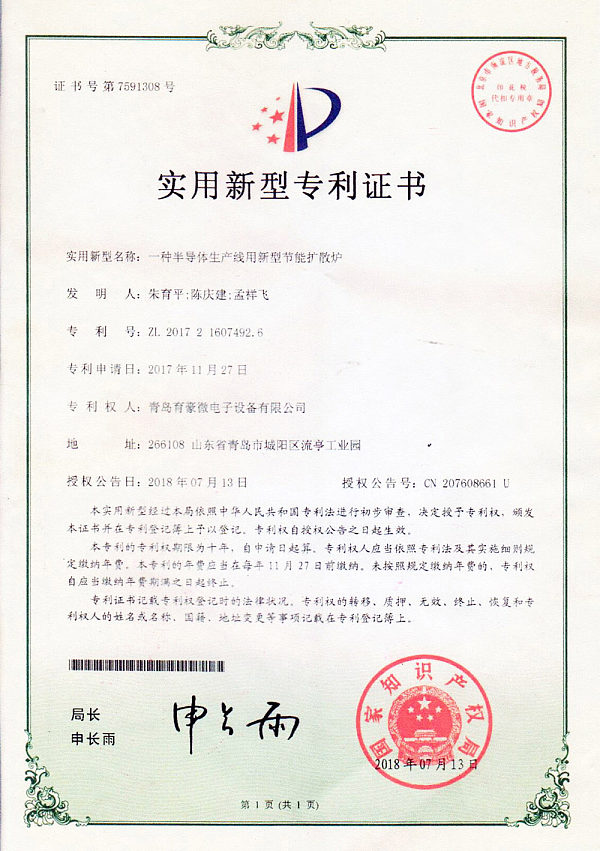

Yuhao is a national high-tech enterprise and a provincial specialized and innovative SME. We hold trademark registration rights and import/export operation licenses, having passed ISO9001 quality management system certification with over 45 patents.

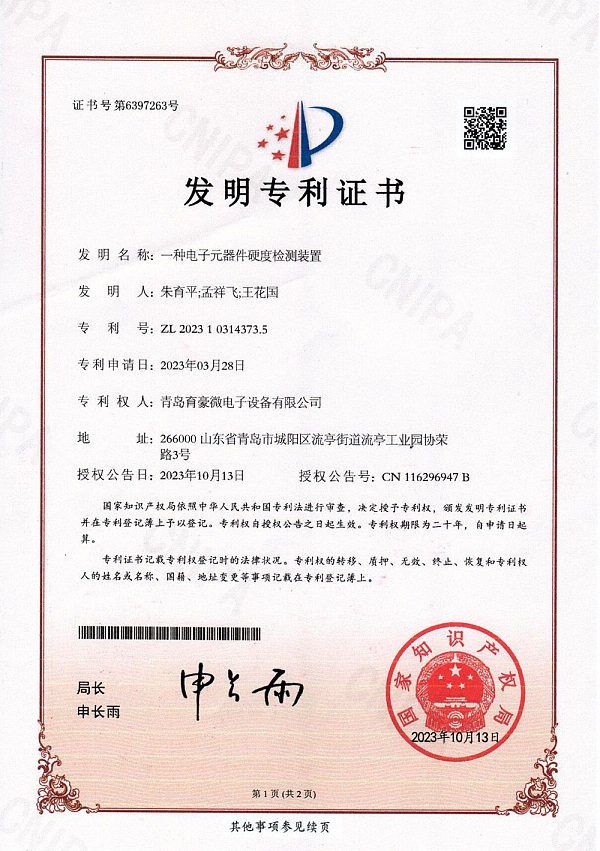

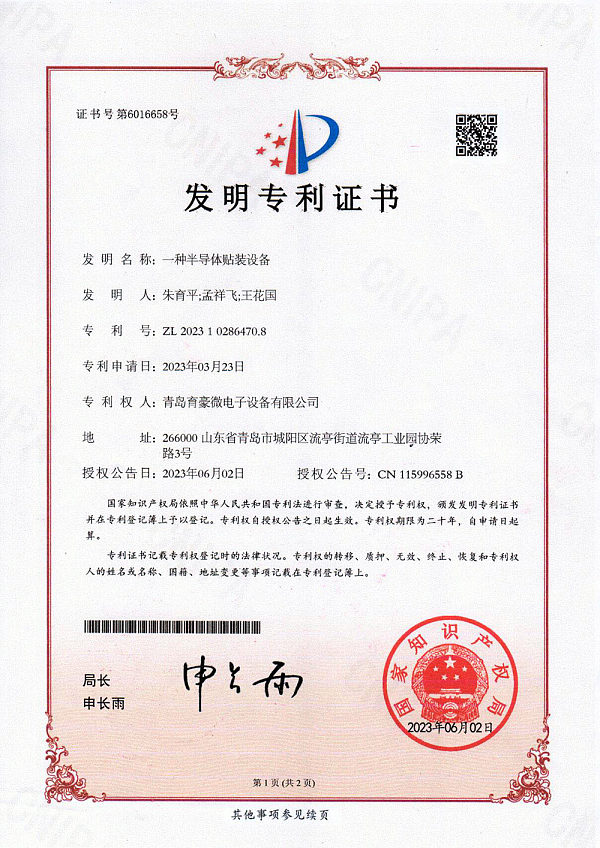

○ Company Certifications

○ Online Consultation

○ Related Recommendations

Message Consultation