Products & Applications

Product Categories

○ Product Details

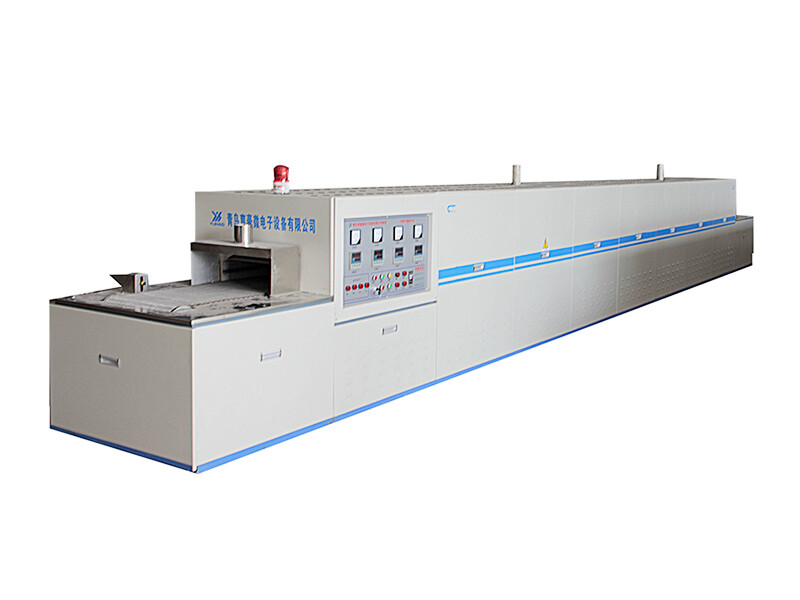

Primarily used for various electronic components, diodes, rectifier bridges, automotive electronics and other products held by tweezers in an ink tool, combined with solder paste, solder strips and other related soldering materials for soldering process production under vacuum or protective atmosphere. Applications include IGBT packaging, soldering processes, laser diode packaging processes, hybrid integrated circuit packaging, tube shell cover plate packaging, MEMS and vacuum packaging. Significantly reduces porosity generated during production, keeping post-soldering product porosity below 3%.

2. Key Parameters:

3. Main Features and Advantages

1. Soldering under vacuum environment with vacuum level <5Pa.

2. Low-activity flux soldering environment.

3. Touchscreen control paired with professional software ensures optimal operational experience.

4. High-precision 40-segment programmable temperature control system allows setting of process curves.

5. Temperature settings feature touch-based rise/fall adjustment; direct manual curve pulling enables process settings closer to material soldering requirements.

6. Water-cooling technology achieves rapid cooling effects.

7. Four-group in-line temperature measurement function ensures effective measurement of soldering zone temperature uniformity, providing support for process calibration.

8. Optional nitrogen, hydrogen or other inert gases to meet special soldering requirements.

9. Designed with real-time process video recording system. Records soldering process for each product, providing strong evidence for quality tracking while supporting R&D and material testing data.

10. Maximum temperature 450°C (higher optional), meeting all soft solder process requirements.

11. Vacuum chamber top cover with observation window for nitrogen environment.

12. Multi-system safety monitoring and protection designs (solder joint over-temperature protection, overall temperature protection, gas pressure protection, water pressure protection, operational safety protection, soldering cooling circuit protection, liquid level protection, power failure protection).

○ Company Profile

Qingdao Yuhao Microelectronics Equipment Co., Ltd. was established in 2008 as a high-tech enterprise integrating R&D, manufacturing, and sales. The company specializes in electric heating furnace equipment, heating furnace thermal fields, and graphite tool processing. Our products and services cater to various industries including electronic components, semiconductor materials, and solar photovoltaic sectors.

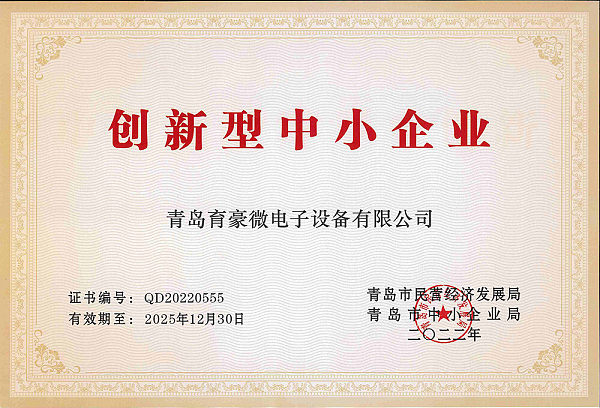

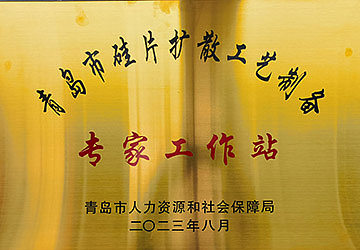

Yuhao is a national high-tech enterprise and a provincial specialized and innovative SME. We hold trademark registration rights and import/export operation licenses, having passed ISO9001 quality management system certification with over 45 patents.

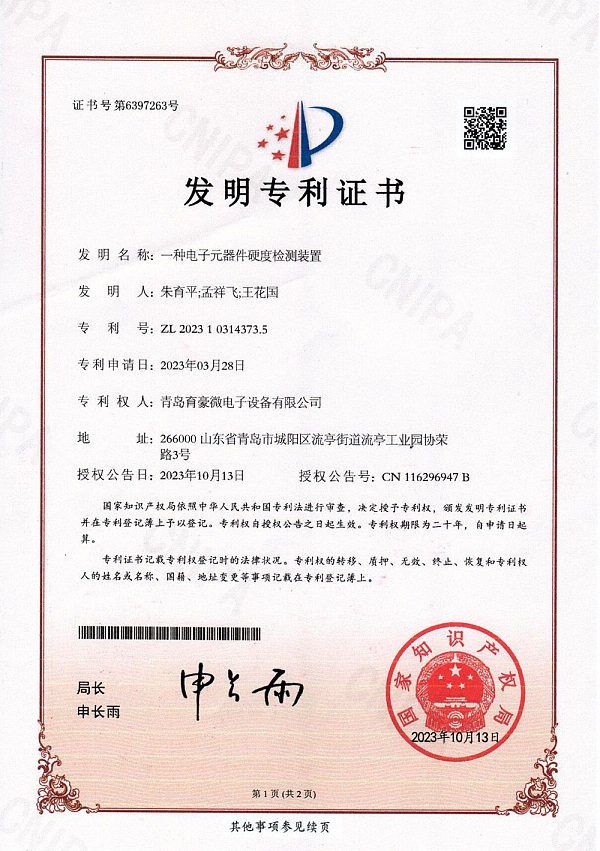

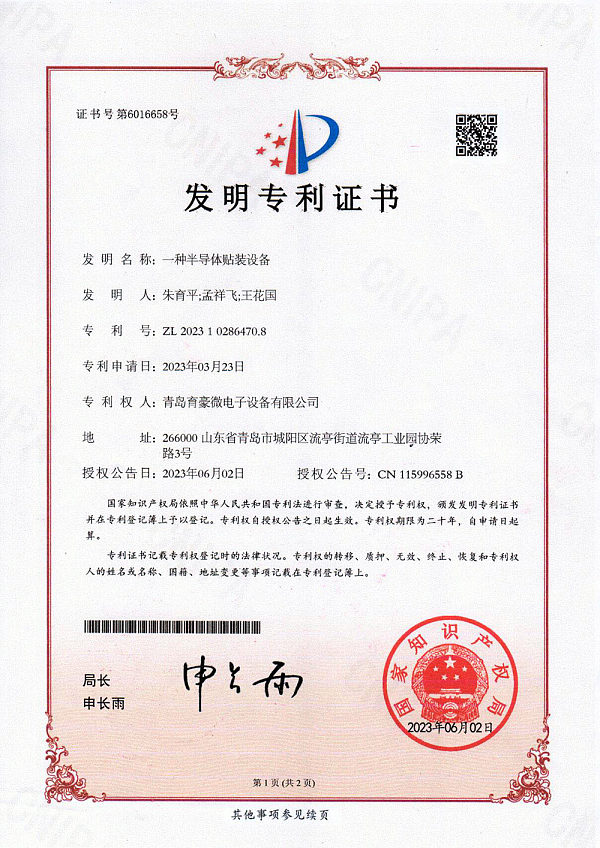

○ Company Certifications

○ Online Consultation

○ Related Recommendations

Message Consultation